Metals Treatment Project Leads to New System Design

The Scenario

When one Georgia-based manufacturing company partnered with new investors, they were prompted to implement a wastewater treatment process where there previously was none. Thanks to our team members’ diverse skillsets and expertise, Operators Unlimited was able to design and implement a fully comprehensive and compliant treatment process from the ground up.

The Problem

This company’s facility, which specializes in the manufacturing and fabrication of metal products, had been discharging directly to the municipality for some time without any parameters or known consequences to reference. However, the waste stream contained significant metals, high concentrations of phosphorous and extreme pH levels. During the manufacturing process, steel components are exposed to an acidic wash designed to remove oils and loose particles. The facility wanted to implement a treatment process for the wastewater produced. So, without a starting point to work from, Operators Unlimited utilized the full depth of all its services in order to deliver an effective solution that would alleviate the strain on downstream municipal systems and quell client concerns.

The Solution

The lack of an existing treatment system created a significant challenge for the OU team, who were unable to collect samples from the waste stream for initial analysis. Thus, installation of an equalization tank was the first phase of what would become a five-step process.

First, raw wastewater enters the equalization tank and is stored there until time to process.

Next, the phosphorous is targeted as phosphorous is the most prevalent contaminant.

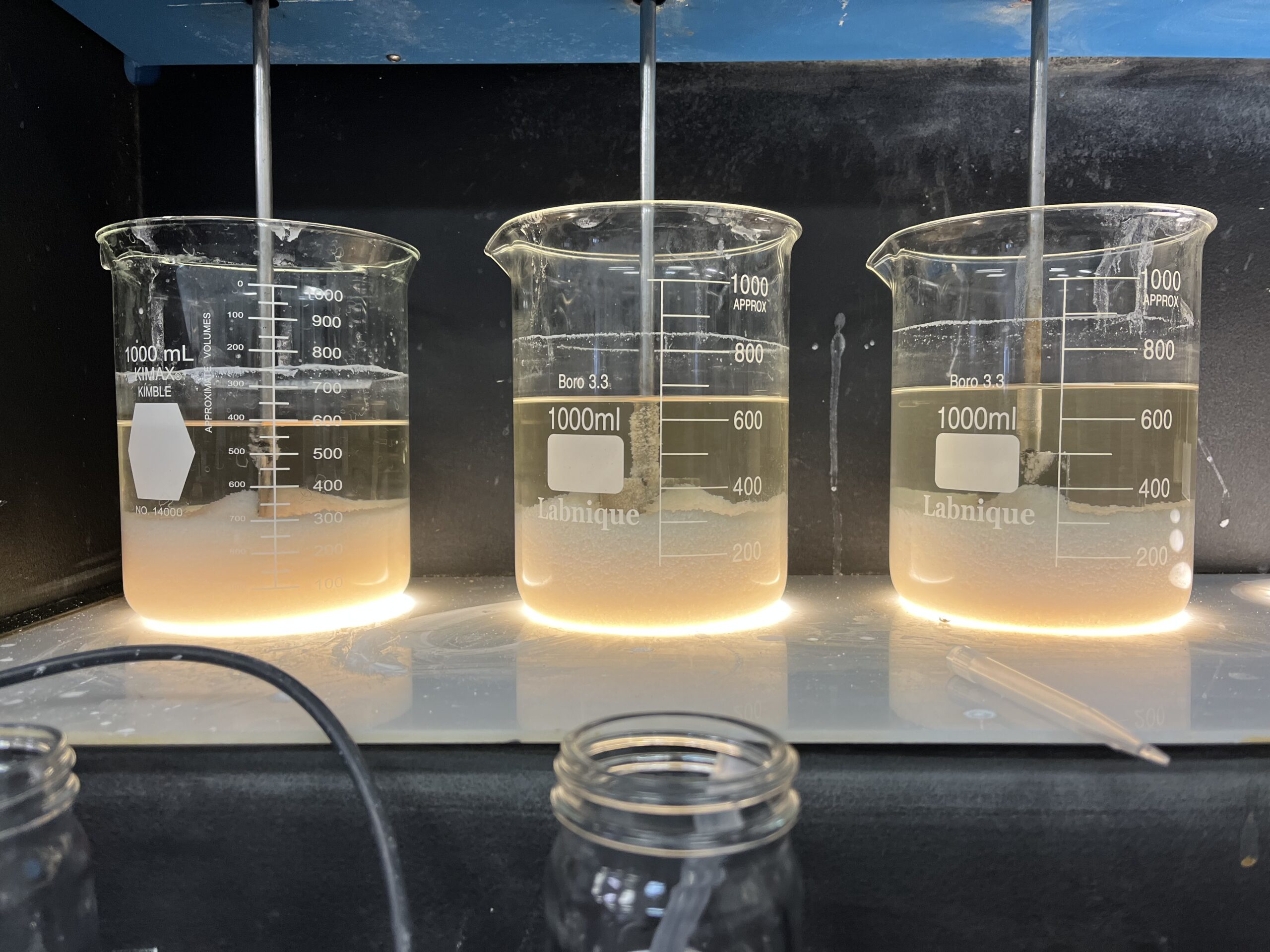

Subsequently, the metals removal phase targets metals and polishes the liquid stream of any remaining phosphorous. This step brings all permitted contaminants down to the permit levels.

All solids are then received post-phosphorus and metals removal for filtration and discharge. A sample location is provided to meet regulatory requirements. In the case of this facility, the toxicity characteristic leaching procedure (TCLP) analysis result was classified as non-hazardous thus reducing costs for disposal.

The Results

Early in the planning stages, the company had expressed the need for design which lent itself to peak efficiency, inspiring the OU team to consider system functionality and longevity at every step. The cost of fully outfitting a brand-new wastewater treatment system came to approximately $850,000; but the foresight evident throughout the system’s design, layout and installation will circumvent future costs by accommodating future increases in processing capacity – despite the exceptionally tight footprint of the long, narrow facility.

OU remained flexible throughout design and implementation. For example, OU was contracted to only provide the EQ tank and metals treatment. During the permitting process, the regulatory agency required phosphorous to be treated as well. The facility then requested the design to include phosphorous removal to meet this requirement. OU responded by redesigning the system for phosphorous removal with a minimum of additional equipment.

Conclusion

The OU team also carefully considered long-term labor costs associated with running the new system. With labor costs reduced by a third, the facility will save approximately $60,000 annually. Lastly, and perhaps most importantly, by choosing to take the initiative in addressing the facility’s wastewater, this company has demonstrated its commitment to upgrading its facility– environmentally and ethically.

Through implementation of the OU treatment process, the facility became fully compliant. This compliance was achieved through three main factors that OU uniquely provides:

- Customized process design to meet customer’s requirements.

- Remaining flexible to the facility’s changing needs

- Actively responding to the facility’s concerns during operations.

At Operators Unlimited, our team takes pride in providing our customer partners with the means to achieve enhanced operational efficiency, no matter the starting point. If your wastewater treatment system needs operational support staff, custom chemistry and process analysis, equipment optimization, design and engineering services or all of this and more, contact Operators Unlimited today to learn how we can help you achieve your facility’s goals.