If your facility uses boilers you know that this is another form of industrial water/wastewater to which close attention needs to be paid. Industrial manufacturing plants utilize boilers to produce heat energy through steam that can be used for multiple purposes. Boilers produce steam or hot water that can be converted to provide heat, sterilization, electricity, and the powering of machines, among other important uses. To keep these boilers operating at peak performance, it is of utmost importance that a regular maintenance program be instigated. After all, everything left to itself tends toward disorder and a boiler in disorder is bad news, causing increased operating costs, and even plant shutdowns.

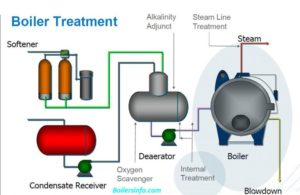

The goal of a water treatment program is to minimize the total operating cost of the boiler system. To do this effectively good quality pre-treatment of the makeup water to the boiler is necessary using softened ordemineralized water. A good quality Deaerator is crucial to reduce Dissolved oxygen as well.

Boiler water treatment is necessary to prevent damage to the boiler, limit harmful deposits and buildup, and to reduce operating costs. Operators Unlimited Boiler Treatment service program can help keep your boiler costs down and operating at peak efficiency by significantly reducing some of the most common issues you deal with such as scale deposits, corrosion.

Below is an overview of some of the problems we can help prevent or solve:

Reduce and Prevent Scale Deposits – Hard deposits, often referred to as scale, can develop within your boiler if not properly maintained. These deposits which usually are made up of elements such as magnesium, iron, silica, and calcium, can be very hard to prevent. OU can provide scale prevention chemicals to keep your system operating efficiently.

Reduce Sludge Buildup – Boiler sludge is not hard deposits like scale but is buildup that occurs in the water inside a boiler tank system. If not properly removed or dealt with regularly, sludge can cause major problems over time. The sludge, which is made of various solid matter, oils, and minerals, can stick to the boiler walls, and even cause blockages. This in turn can cause a lack of heat transfer, decreasing the boiler’s performance, increasing the cost of operation and even system failure if not dealt with properly. Our Boiler experts can offer solutions for the maintenance of your system, including suggesting one of our chemical products to help preventor reduce the buildup of sludge in the future.

Reduce Sludge Buildup – Boiler sludge is not hard deposits like scale but is buildup that occurs in the water inside a boiler tank system. If not properly removed or dealt with regularly, sludge can cause major problems over time. The sludge, which is made of various solid matter, oils, and minerals, can stick to the boiler walls, and even cause blockages. This in turn can cause a lack of heat transfer, decreasing the boiler’s performance, increasing the cost of operation and even system failure if not dealt with properly. Our Boiler experts can offer solutions for the maintenance of your system, including suggesting one of our chemical products to help preventor reduce the buildup of sludge in the future.

Prevent Corrosion and Cracks – Unless you want expensive repairs or to replace your boiler, it is crucial that the prevention of corrosion be a priority. This is a constant battle for most facilities, but a boiler water treatment program can ease your struggle and worries. Most problems with corrosion in a boiler system are related to the chemical makeup of the water. That is why it is important to maintain a proper balance of the dissolved oxygen and solids, as well as the acidity level of the water. In fact, a low pH level is often one of the biggest causes of corrosion in a boiler system. OU provides several chemical products or can develop a custom blend that can help to maintain a proper pH level in your system.

Defoaming and Preventing Foam – Another major concern is contaminants leaving the boiler tank and causing deposits to form in other parts of the system such as valves, turbines, etc. This is often referred to as carryover. Not only can dissolved oxygen, dissolved solids, and alkalinity contribute to corrosion, but they also can contribute to chemical carryover. One way this can happen is in the unwanted production of foam. Not all foaming in boiler systems is caused by chemical causes. Some foaming can be caused just by the design of the system. To remedy the problem with foaming, an OU specialist can diagnose and propose one of our anti-foam agents or defoamers.

These are just a few of the more common issues faced by plants utilizing boilers in their operations. Contact Operators Unlimited to discuss your system or issue. We would love to visit your plant and develop a maintenance program or suggest an OU Boiler Treatment chemical to make your boiler more efficient and your life easier.