If you have been awake and out of bed today for at least 5 minutes, you probably have already been in contact with a polymer-containing product. In fact, polymers touch almost every area of our lives in modern times. They help form the basic structure of materials we experience every day like plastic, rubber, glass, and even concrete. But according to the Encyclopaedia Britannica, polymers also “make up many of the materials in living organisms, including, for example, protein, cellulose, and nucleic acids.”

In simple terms, a polymer is a class of substances that are made up of chainlike, large molecules that are themselves made up of smaller molecules called monomers. Monomers join together to form the polymers. There can be a multitude of monomer molecules in one polymer molecule, the more there are the stronger the polymer chain.

The very nature and structure of the polymer molecule makes it useful for so many industrial uses. In fact, you would be hard pressed to find an industrial manufacturer that does not use some form of polymer in its operation. For more on the many uses of polymers and their makeup, check out this article from Livescience.com.

So why are polymers such a good product to use in the wastewater treatment process? The versatility of polymers makes them not only useable in the manufacturing process but also in the treatment of the “dirty” water that is produced during the process of manufacturing. Polymers are also helpful to municipalities in the sewage treatment process.

Often in dealing with wastewater the challenge is how to separate the “dirty” particles out of the water to produce a “clean” effluent. If you are experienced in working with wastewater, you probably just read that statement and said, “thank you captain obvious.” But what is such an obvious principle, as you know, is not a simple process. Polymer products help aid in this process, because many of them can be used to coagulate particles, thus making it easier to separate them out. In coagulation, polymers can be used to cause particles to join together in large chains (called floc) making them “come out” or begin to “settle out” of the water. This then makes the rest of the treatment process more manageable, beginning to create solids that can be dewatered, or moved along to another process. For more information on the coagulation process, see our short primer on coagulants.

Operators Unlimited sells many different polymer products that aid in the wastewater treatment process. In fact, we often create custom blends for many industrial manufacturing companies based on the makeup of their wastewater. After all, in wastewater treatment, particularly in manufacturing, “one size does not fit all,” so to speak, as each manufacturing process includes so many different variables.

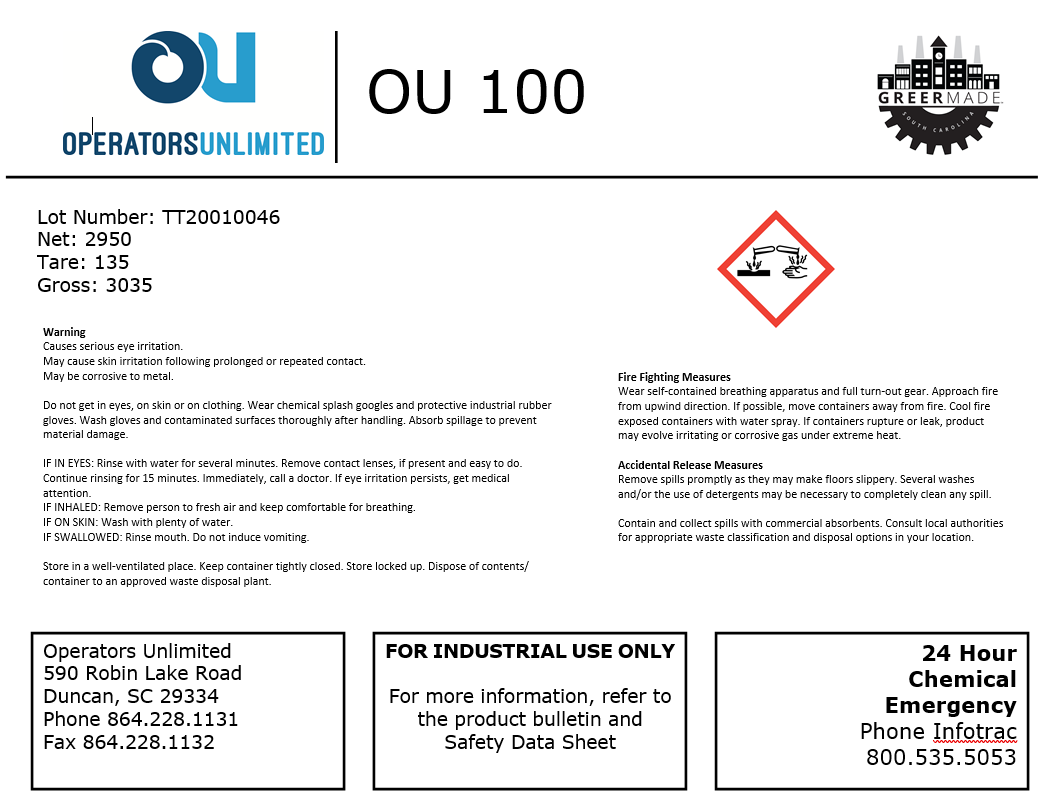

One product of ours that both municipalities and manufacturing companies have found to be particularly effective, is our polymer blend coagulant, OU 100. This is our most popular blended coagulant. Comprised of a proprietary blend of inorganic and organic coagulant components, OU 100 is very versatile and is currently being used very successfully in a variety of industries and applications including: Metals Plating and Finishing wastewater, Food and Beverage wastewater, Municipal wastewater, Sequential Batch Reactor coagulation applications, and Other Industrial pretreatment wastewater operations.

OU 100’s specialty components lead to an improved floc particle when compared to other coagulants. This results in better settling, cleaner & clearer water, and typically a reduction in, or total elimination of, polyacrylamide flocculants, which creates cost savings and simpler operation. Lastly, the components of the blend also lead to improved oily waste coagulation when compared to other coagulants.

Our specialists can test your wastewater and determine if OU 100 is an efficient solution for your organization. If not, we can develop a blend for you. Click here for more on our products.