When it comes to wastewater treatment there are many chemicals that can aid in the process. These chemicals perform 6 main roles in the treatment process, each providing a key function. These functions include: Removal of solid particles, pH Adjustment, Odor Control, Disinfection, Foam Prevention & Removal, and Sludge Removal. What follows is a quick primer on many of the chemicals used in wastewater treatment and these six main functions that they perform. Of course, there are a few other ways chemicals in wastewater treatment are used, but we will only deal with these six in this article.

One of the biggest challenges in wastewater treatment is the removal of solid particles from the water. Recently, one of our specialists taught a full class on the Science of Solids/Liquids Separation at one of our FREE CEU Workshops. This can be a fun study for those interested in the chemistry involved in the process. Several kinds of chemicals can aid in the process of removing solid particles from the water.

One of the biggest challenges in wastewater treatment is the removal of solid particles from the water. Recently, one of our specialists taught a full class on the Science of Solids/Liquids Separation at one of our FREE CEU Workshops. This can be a fun study for those interested in the chemistry involved in the process. Several kinds of chemicals can aid in the process of removing solid particles from the water.

Coagulant and Flocculant Polymers are important in this process. These polymers help the tiny particles in the water to begin to combine with each other to form larger particles and chains of particles that settle out of the water and drop to the bottom. Basically, the polymers are used to change the “charge” of the particles so that they will combine with rather than repel other particles. For more on the coagulation process see our article “Wastewater Processes Part 1: A Short Primer on Coagulants” . For even more information, also read our article on flocculation: “Wastewater Processes Part 2: How are Flocculants used in Wastewater Treatment?.” Other chemicals used in other applications in this process are alum and ferric sulfate and ferric chloride, aluminum sulfate, among others.

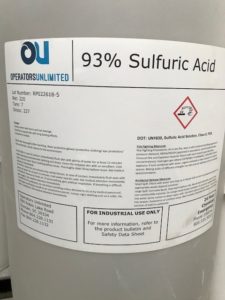

A second use of chemicals in wastewater treatment, is to adjust the pH level. Almost every industrial manufacturing company and wastewater treatment operation deals with pH Adjustment on some level. Their local POTW and more importantly DHEC will require the effluent from a plant to be within a certain range or at a certain pH level before it can be released or disposed of. Obviously either an acid or a base chemical will be used, depending on the pH level of the water. The most used acid is Sulfuric Acid. This is due to its cost, abundance, and effectiveness in adjusting the pH level. Other acids that are used include Hydrochloric Acid and Phosphoric Acid. As far as bases, some common chemicals that are effective are Sodium Hydroxide, Calcium Hydroxide (Lime), among others. Operators Unlimited provides bags of Hydrated Lime to many plants including  adhesives manufacturers. Click here for more about all of our product categories.

adhesives manufacturers. Click here for more about all of our product categories.

Often, as a result of processing food, or in some other process at an industrial plant, the wastewater produces odors that are not only unpleasant but that can also be harmful. Odor Control is another key function for the use of chemicals in wastewater. We are primarily discussing wastewater treatment in an industrial setting, but sometimes industrial plants are faced with some of the same problems with odors as municipal wastewater treatment plants. Unpleasant odors produced by the wastewater can impact employee morale, invite complaints from neighbors including other businesses, and even be a health hazard. It is a major issue that must be solved. For most industrial plants something more must be done than just “covering up” the problem to contain the odors. Because of this, Operators Unlimited, offers multiple technological and chemical solutions to remedy the problem. We have developed misting solutions to deodorize the air, but we also offer several high performing odor controlling chemicals like our OC 150.

Another use of chemicals in wastewater is for Disinfection. Commodity chemicals, like Bleach, produced in various concentrations, are often used for this purpose. One common concentration that OU offers, is our Sodium Hypochlorite 12.5%, but we offer other concentrations as well. Bleach is used for disinfection and production processes in all kinds of industrial applications including coatings, food processing, paper & packaging, pharmaceuticals, and more.

Often foam can develop in the wastewater treatment process, which can cause many problems. In fact, the foam can stand in the way of measuring instruments getting a true reading and can cause other difficulties. For more on how foam can develop in wastewater, see our article “What causes foam in wastewater treatment.” In order to effectively treat wastewater, in some applications, there needs to be either Foam Prevention or Removal. To settle down the foaming in wastewater a Defoamer product, like our OU 365, can be added. To prevent foam from occurring,  an Anti-foam chemical agent can be used.

an Anti-foam chemical agent can be used.

One other use of chemicals in wastewater treatment is for the purpose of Sludge Removal. The water must be removed from the sludge that is created in the wastewater treatment process. Often polymer chemicals are re-introduced into this stage of treatment to remove the water. Polymer chemicals like our OU 100 can be added to the wastewater to aid in the process in conjunction with the use of presses, and geotextile bags. We have assisted multiple customers in various industries with their sludge removal needs.

Whatever your chemistry needs are, OU has a solution for you. We know that “a one size fits all” approach to wastewater seldom solves problems, so contact us to survey your wastewater plant and to develop a solution. Our specialists can do a jar test for you and determine a custom blend or existing OU product to solve your wastewater challenges. Click here to get the process started.